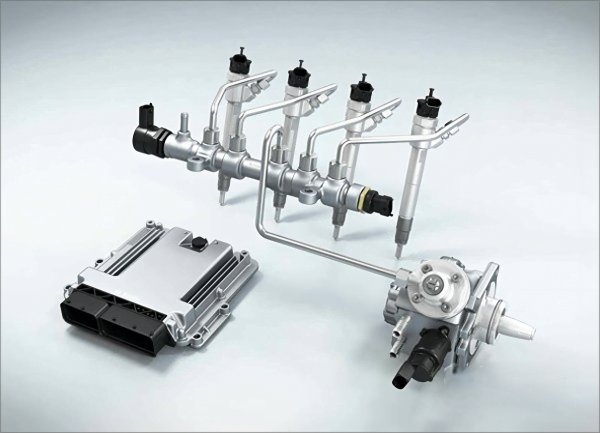

With the rapid development of automotive technology, especially in the field of diesel engines, high-pressure common rail technology has become the core of modern diesel engines. As a system that precisely controls fuel injection, it not only improves engine performance, but also significantly reduces emissions. However, due to its complexity, the skills required of technicians are also getting higher and higher. Therefore, professional high-pressure common rail technology training is particularly important. This article will explore why this training is crucial and the best way to learn it.

Why is high pressure common rail technology training important?

Improve technical level

The high-pressure common rail system has extremely high working pressure, involving precision parts such as injectors and high-pressure pumps. For technicians who haven’t received special training, repairing and maintaining these parts may lead to misoperation and affect system performance. Through professional training, technicians can gain a deeper understanding of the working principles of these parts and improve their operation and diagnostic skills.

Extend engine life

Regular maintenance and accurate fault diagnosis help keep the engine running longer. Technicians trained in high-pressure common rail technology can better detect potential problems. This allows them to take timely measures, extending engine life and reducing maintenance costs.

Enhance safety

The high-pressure common rail system operates with high-pressure fuel, and improper handling can result in safety hazards. Proper training ensures that technicians follow safety regulations and avoid dangerous situations caused by incorrect operation.

The best way to learn high pressure common rail technology

Theory Study

Theory is the foundation of technical practice. Through classroom instruction or online courses, technicians can systematically learn about the structure, working principles, and common faults of high-pressure common rail systems. Video explanations, graphical demonstrations, and real case analyses can help students better grasp the knowledge.

Hands-on Practice

While theory is important, practical training is the core part of developing technical skills. Disassembling, assembling, and adjusting systems on actual equipment can help students turn their theoretical knowledge into practical skills. This kind of training is typically conducted in professional training centers or well-equipped workshops.

Training with Simulators

Simulators provide a safe and effective way to train. By simulating real operating environments and fault conditions, technicians can practice troubleshooting and system adjustments in a virtual environment. Simulators not only help technicians improve their skills but also reduce the risks that may arise from operating real equipment.

Certification and Assessment

Certification exams can test whether students have truly mastered high-pressure common rail technology. These certifications, usually issued by authoritative industry bodies or equipment manufacturers, can provide technicians with more career opportunities and security.

Continuous Learning to Stay Ahead

Technology is constantly evolving, so regularly participating in training and technical seminars is crucial for staying competitive. Many manufacturers regularly offer new training courses, and technicians can also stay updated on the latest trends and technological developments through industry forums and technical conferences.

Conclusion

High-pressure common rail training boosts technicians’ skills and ensures safe, efficient engine operation. Through theory, hands-on practice, and ongoing training, technicians can keep up with modern diesel technology, adding value to the industry.

If you’re a technician or simply interested, consider joining a professional course to dive deeper into this technology.

About Us

Bokk Tech specializes in various diesel common rail injector and pump testers and drivers, supporting testing of various brands such as Bosch, Delphi, Denso, Siemens, etc. The test bench can be customized according to your needs. We also provide related accessories such as injectors, plungers, etc.

Share The Post