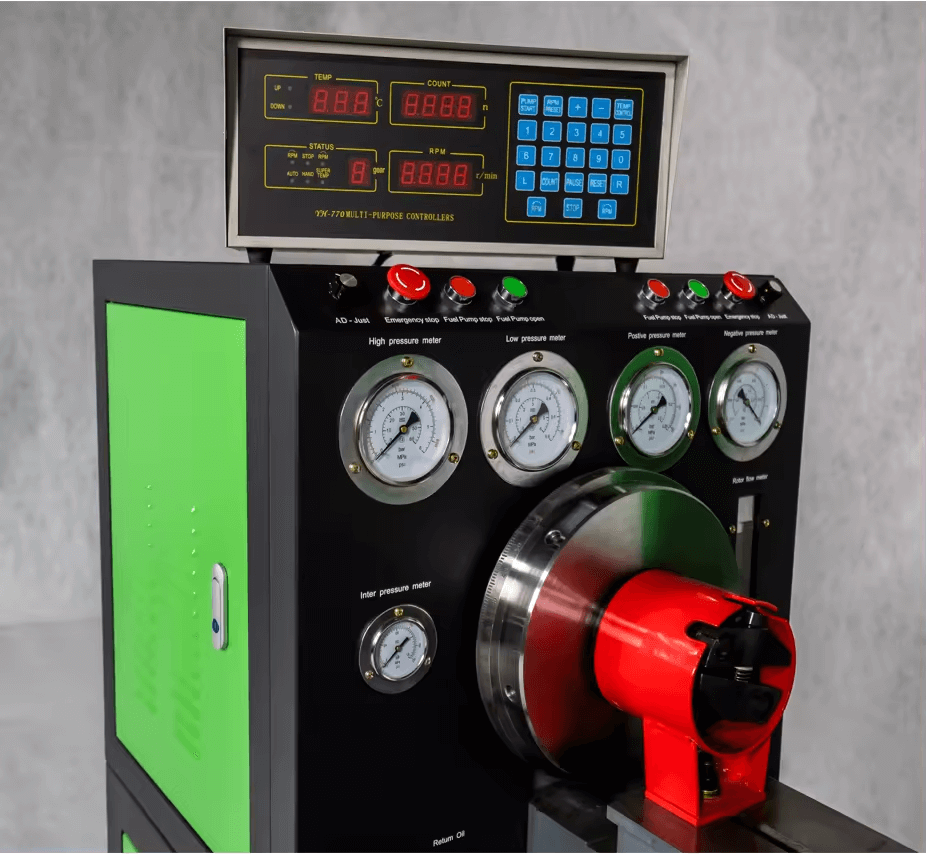

High-pressure common rail testing equipment is essential in the automotive repair industry. The accuracy and stability of this equipment directly impact the reliability of test results. Maintaining the equipment in optimal condition and prolonging its lifespan are crucial for boosting efficiency and cutting operational costs. Below are some key maintenance tips to help you keep the equipment in top shape.

Clean the Equipment Regularly

Maintaining a clean environment for your equipment is essential for extending its lifespan. Regularly wipe down the exterior with a lint-free cloth and a neutral cleaner to prevent dust and grease buildup, which can interfere with heat dissipation and performance. For internal components like circuit boards and fans, use compressed air to clean them regularly, ensuring that dust doesn’t accumulate and compromise heat dissipation or circuit stability.

Inspect and Replace Filters Promptly

Filters are crucial in keeping dust, grease, and other impurities from entering the equipment. Regularly check and clean the filters to ensure they remain clear. If a filter is damaged or no longer effective after cleaning, it should be replaced immediately. This will protect the equipment’s precision components from potential damage caused by foreign particles.

Regular Calibration

The accuracy of your equipment depends heavily on regular calibration. It’s recommended to calibrate the equipment every 6 to 12 months, depending on how often it’s used. Use the calibration tools recommended by the manufacturer and follow the instructions carefully to ensure the equipment consistently delivers precise results. Regular calibration not only extends the equipment’s lifespan but also enhances work efficiency and the reliability of test outcomes.

Maintain an Optimal Working Environment

The equipment’s working environment directly impacts its performance and longevity. Keep the temperature between 15°C and 25°C and the humidity between 40% and 60% to avoid damage from extreme conditions. A well-ventilated space prevents overheating; if necessary, use air conditioning or dehumidifiers to regulate the environment.

Handle faults promptly and strengthen operation training

If the equipment shows any signs of malfunction, shut it down immediately for inspection. Resolving minor issues early prevents them from escalating. Regular maintenance and prompt repairs are essential for prolonging the equipment’s lifespan. Additionally, ensure that all operators receive professional training and understand the correct operation and maintenance procedures. This reduces the risk of equipment damage due to improper use.

By applying these maintenance tips, you can significantly extend the lifespan of your high-pressure common rail testing equipment, maintain its stable operation over time, boost work efficiency, and reduce the inconvenience of unexpected failures.

Share The Post