Mainly focus on the following aspects:

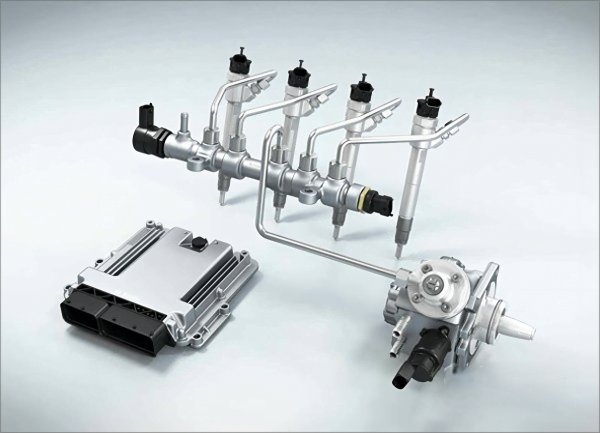

1. Ultra-high pressure injection:

The injection pressure of modern common rail systems is constantly increasing, reaching 200 MPa or even higher. This high-pressure injection can significantly improve the fuel atomization effect and combustion efficiency, and reduce the emission of particulate matter and nitrogen oxides.

2. Controllable injection rate:

By precisely controlling the injection rate, the combustion process can be optimized, emissions can be reduced and engine efficiency can be improved. This requires high-precision solenoid valves and advanced control algorithms.

3. Multiple injection technology:

Modern common rail systems are able to perform multiple injections within a working cycle, such as pre-injection, main injection and post-injection. This technology helps to reduce noise and emissions while improving combustion efficiency.

4. Intelligent diagnosis and monitoring:

Common rail fuel injectors are increasingly integrated with intelligent diagnostic functions, which can monitor the working status of the injector in real time and detect and diagnose faults in a timely manner.

5. High-precision test equipment:

Inorder to meet these technical requirements, common rail fuel injector testers are also constantly upgraded with higher test accuracy and faster response speed.

These technical trends have jointly promoted the development of diesel engines towards a more efficient and environmentally friendly direction.

If you are interested in more specific aspects, please let me know!